COMPANY

PRODUCTS

PR CENTER

SUPPORT

Inovative

Technology

Technology

HOME

Products

Hot Melt Laminating M/C

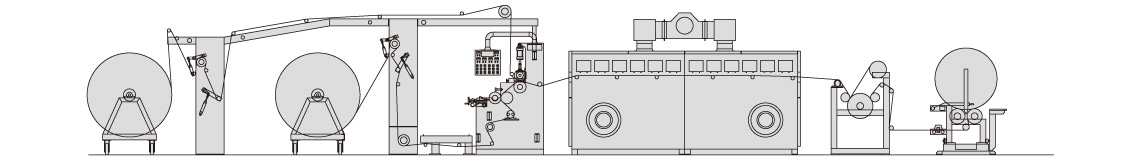

Hot Melt Laminating M/C

WF-2030N

Features & Application

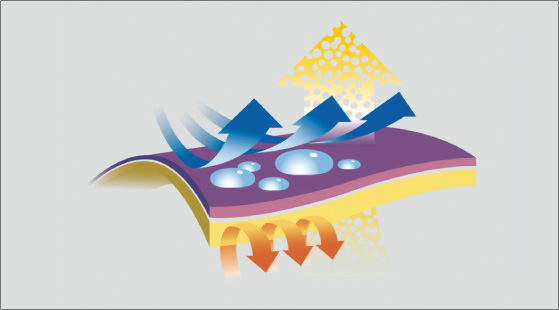

- Thermosetting Resin (=Moisture Stiffening Resin) : PUR

- Thermoplastic Resin : EVA(ethylene-vinyl acetate), PA(Polyamide),

PET- OPTION - Environment-Friendly as Solvent Free

- Less space by compact design

- No need of dedicated drying device

- No need of auxiliary device like Boiler

- Excellent bonding effect

- Available to laminate with PTFE, TPU, ePTFE and PU membrane film, Nano film etc.

- Sportswear, Home textile, Medical cloth, Shoes, Automotive interior materials, Furniture, Carpet and Non-woven textile, Sanitary pad, diaper, Mask etc

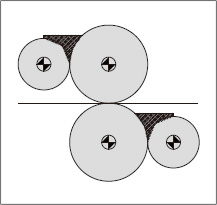

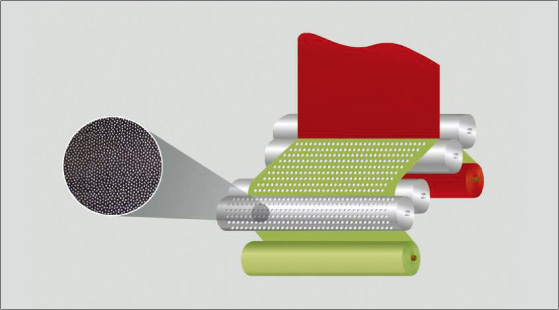

Coating type

-

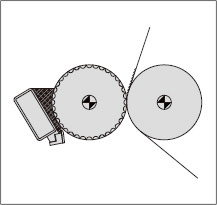

Dot & Gravure

-

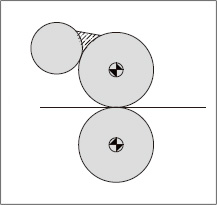

Roll Coating

-

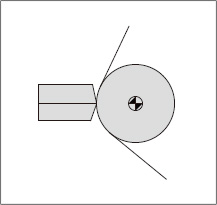

Slot

-

Both Coating

-

Spray

-

Structure of Fabric

-

Hotmelt Laminating Process

Supply & Head Device

-

Hot Oil Heater

-

Head Part

-

Hot Melt Applicator

-

Roll Cleaner

Specification

| Model | WF-2030N | WF-2030 | WF-2010BC |

|---|---|---|---|

| Roller Width |

2,000 ~ 2,500mm |

2,000 ~ 2,500mm |

2,000 ~ 2,500mm |

| Working Width | Max. 1,800~2,400mm | Max. 1,800~2,400mm | Max. 1,800~2,400mm |

| Working Speed | Min. 5m/min ~ Max. 50m/min | Min. 5m/min ~ Max. 50m/min | Min. 5m/min ~ Max. 50m/min |

| Electric Capacity | Dot roll, Gravure | Dot roll, Gravure | Dot roll, Gravure |

| Coating Method | 120kw | 120kw | 120kw |

| Driving Method | Servo & Inverter | Servo & Inverter | Servo & Inverter |

※ The specifications are subject to change without any prior notice for quality improvement.

* Move left and right

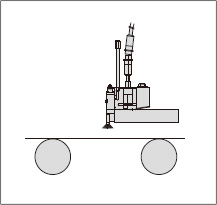

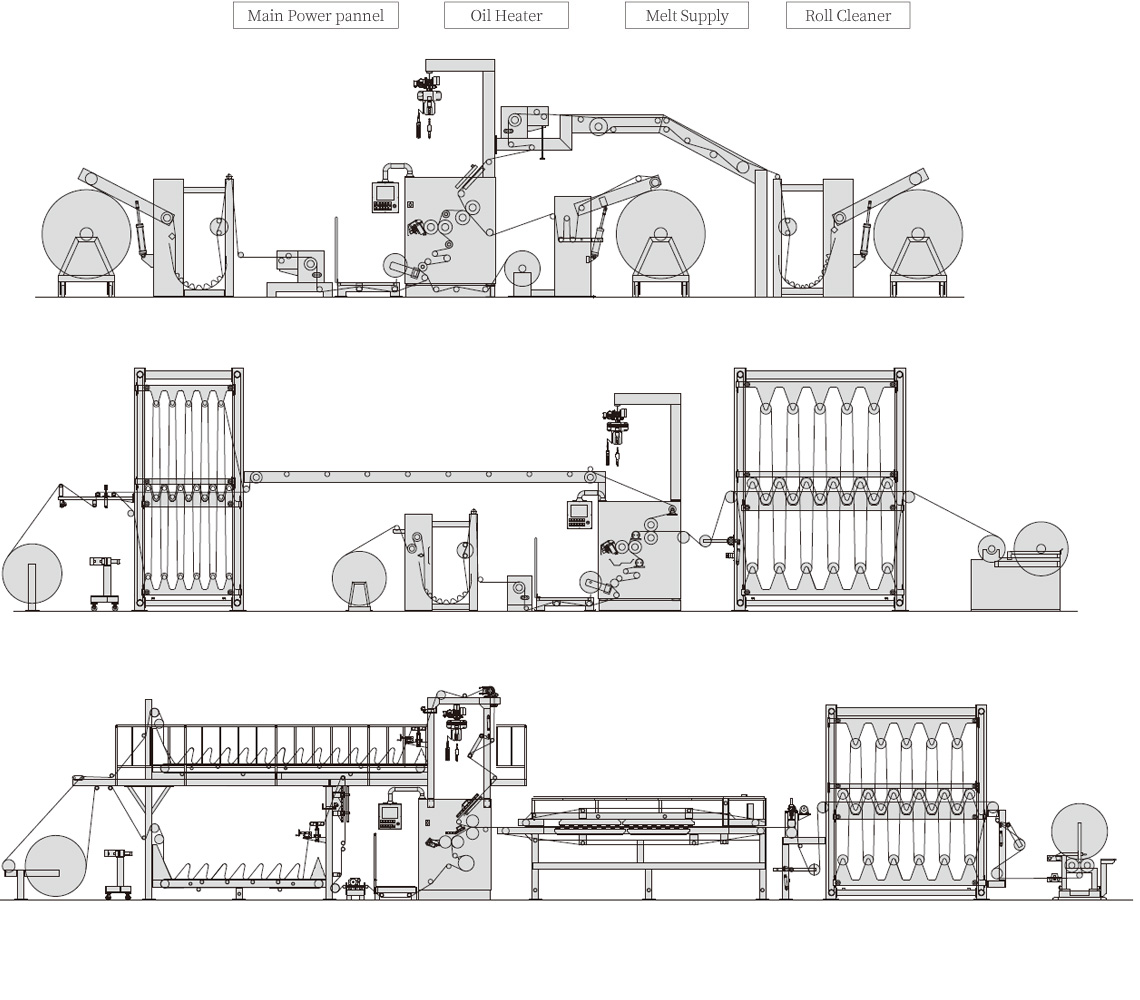

Drawing

WF-2030N (Standard type)

WF-2010BC (Bonding machine)