|

|

|

|

|

| |

PRODUCT > WF-2005 PRODUCT > WF-2005 |

|

|

| Front |

| |

|

| Back |

| |

|

|

|

|

|

| Burner & Main Laminating Unit |

|

Burner |

|

Back Unit |

|

|

|

|

|

| Front |

| |

|

| Back |

| |

|

|

|

|

|

| Burner & Main Laminating Unit |

|

Burner |

|

Back Unit |

|

|

|

|

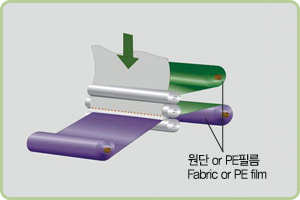

- Possible to laminate more than 2 kinds of material like normal fabric, non-woven fabric and paper with sponge(=urethane foam) by using thermoplastic resin.

- The machine briefly consists of sponge feeding unit & conveyor, fabric feeding unit & conveyor, burner & main laminating unit, accumulator, cutting unit and winding unit.

- Easy to control the feeding of material on laminating.

- Comfortable bending after lamination.

- Minimizing tension on the fabric by accumulator after lamination.

- High productivity by high production speed.

- Car seat, Car headliner(3-Layer Laminating), Carpet, Furniture, Medical cloth(Moquette), Non-woven fabric, Artificial leather, Normal garment, Bags and Gas singed textile etc.

|

|

| |

Flame Laminating Process |

|

|

|

|

|

|

|

|

|

|

- Easy for Sampling

- Less space by compact design

- Car seat, Car headliner(3-Layer Laminating), Carpet, Furniture, Medical cloth(Moquette), Non-woven fabric, Artificial leather, Normal garment, Bags and Gas singed textile etc

|

|

| |

|

|

|

| Winding dia |

Max. Ø1,200 |

| Working width |

Max. 1,800~2,000mm |

| Working speed |

Max.50m/min |

| Accumulator capacity |

About 28m |

| Electric capacity |

45kw |

| Required floor space |

L24,344 x W 5,425 x H6,340mm |

| Burner system |

Gas pressure(Butan) |

2,500 ~3,000mmaq |

| Gas consumption |

9kg/h |

| Air/Gas ratio |

V= 3㎥ : 1㎥ |

| Burner Flame Tempurature |

1,200℃ |

| * The specifications are subject to change without any prior notice for quality improvement |

|

| |

|

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|

- Laminating of thermal deformation by direct heat.

- Possible to laminate either 2 layers or 4 layers simultaneously.

- Interlining(Powder coating laminating), Automotive interior materials, Industrial materials, Various kinds of thermoplastic hot melt film bonding.

- Working Temperature : Max 230 degC.

|

|

| |

|

|

| Main body |

Input conveyer |

|

|

| Input |

Take out |

|

| |

|

|

|

| * The specifications are subject to change without any prior notice for quality improvement |

|

|

|

|

|